Number of clients served

direct users

Number of products sold

sets of Hoist sold annually on average

Number of countries

Average delivery time

Partners

agents and distributors

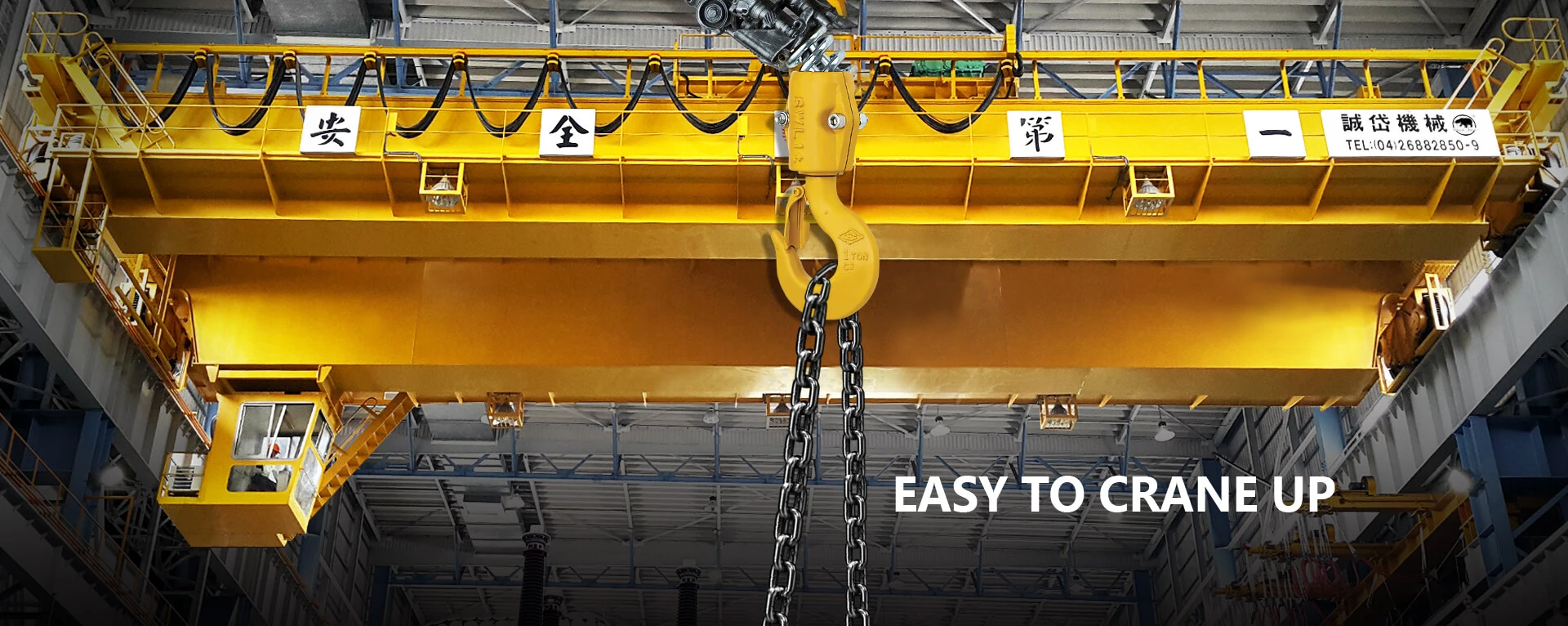

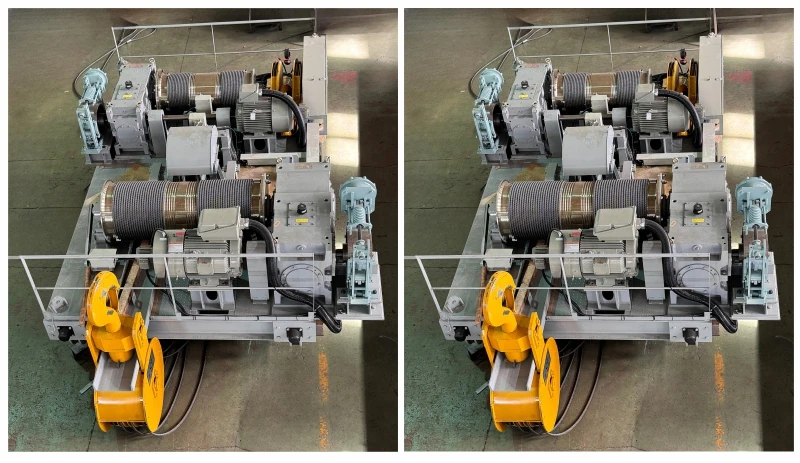

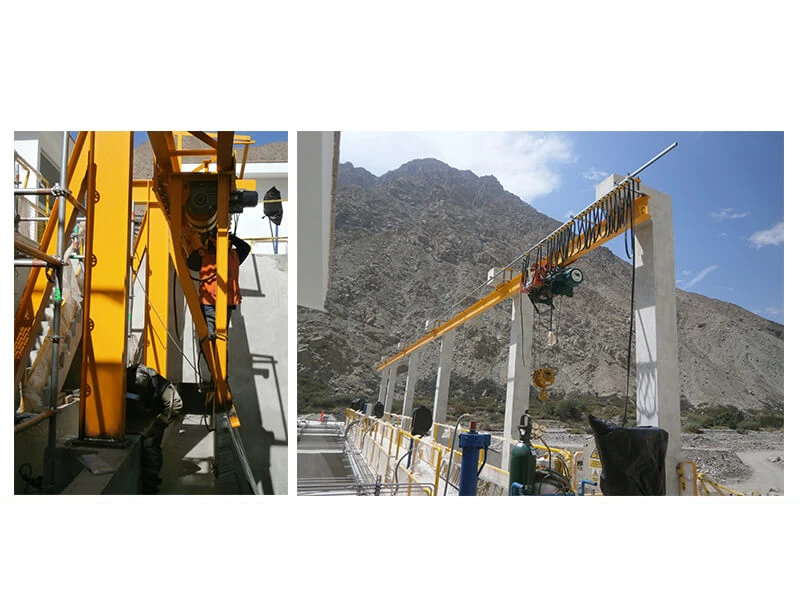

Cheng Day International Group excels in hoisting equipment manufacturing. We have 4 business departments: crane & hoist, elevator, parking system, and heavy duty.

We are devoted to marketing plans, product design, manufacturing, tests, installation, and after-sales services.

ESG

Environmnetal

-

Carbon Reduction and Energy Management

Cheng Day International Group has implemented energy-saving and carbon-reduction technologies and invested in advanced equipment to reduce energy consumption and carbon emissions during the production process. Our goal is to reduce our carbon footprint by 20% by 2025.

-

Resource Recycling and Waste Management

We promote waste reduction and resource recycling policies, optimizing resource utilization to ensure that every link in the industrial chain meets environmental requirements.

-

Biodiversity Protection

Cheng Day actively participates in nature conservation programs and is committed to supporting biodiversity protection initiatives.

Social

-

Employee Welfare and Development

We provide regular training, health management programs, and safety measures for our employees, creating a positive working environment and enhancing their quality of life.

-

Social Contribution and Community Engagement

Cheng Day International Group actively engages in public welfare activities, supports education and social welfare, and makes annual donations while participating in environmental and community projects.

-

Supply Chain Management

We ensure that all suppliers adhere to social responsibility and ethical standards, regularly evaluating their social and environmental performance.

Governance

-

Governance Structure

Cheng Day International Group has a robust governance framework. The Board of Directors regularly reviews company operations to ensure that every decision aligns with our corporate mission and values.

-

Transparency and Information Disclosure

We are committed to maintaining transparency in both financial and non-financial information, regularly disclosing the company’s operational status to shareholders and the public.

-

Risk Management and Compliance

Cheng Day International Group strictly follows international standards, implements risk management plans, and ensures a high level of compliance in all business operations.

.webp)

.webp)