Reliable Electric Hoist Supplier for Your Lifting Needs

Cheng Day, with over five decades of expertise in electric chain hoist manufacturing, stands as a beacon of reliability and innovation in the industry. We boast patents for parts in electric hoists and continuously develop new models to meet evolving market demands.

Where Can You Use Electric Hoists?

Cheng Day electric chain hoists exemplify innovation and reliability, offering a seamless lifting experience for a diverse range of applications across various industries including:

Manufacturing Factory

Streamline your manufacturing processes with Cheng Day electric chain hoists, facilitating the movement of materials and products along assembly lines with unparalleled efficiency and precision.

Construction

From lifting heavy equipment and building materials to positioning structural components, our electric chain hoists are indispensable tools for construction projects of any scale, ensuring safe and efficient operations on-site.

Warehousing

Optimize warehouse operations by utilizing Cheng Day electric chain hoists for lifting and maneuvering heavy inventory, maximizing storage space, and enhancing workflow efficiency.

Maintenance and Repair

Simplify maintenance tasks and equipment repairs with the precision control and reliable performance of Cheng Day electric chain hoists, minimizing downtime and maximizing productivity.

How Do Electric Hoists Work?

An electric hoist operates by utilizing electrical power to lift heavy loads safely and efficiently. Firstly, the hoist is securely fixed onto a suitable anchor point, such as a jib crane or gantry crane, capable of supporting the weight of the load. Once in place, the chain or wire rope is lowered from the hoist and attached to the load, often using lifting accessories like slings to ensure even weight distribution.

With the load properly secured, the operator initiates the lift using a handheld remote control. It's crucial to pause momentarily once the load is just clear of the ground to perform a test lift, ensuring stability and security before continuing the ascent. This precaution minimizes the risk of accidents or injuries during the lifting process.

Electric hoists typically incorporate various safety features to enhance operational safety. These may include safety catches on hooks to prevent accidental disengagement, clutch systems that slip at preset torque levels to prevent overloading, and mechanisms that automatically engage the chain if the hoist is overloaded. Additionally, newer models may feature emergency cut-off switches for added safety in critical situations.

What Sets Our Electric Chain Hoists Apart?

Electric chain hoists are indispensable tools in a wide array of industries, providing powered assistance for the vertical movement of heavy loads. Cheng Day's electric chain hoists are distinguished by their exceptional functionality, safety features, and versatility, making them the preferred choice for discerning buyers. Here's why you should choose our electric chain hoists:

Dependable Safety Protection

The pendant control voltage is transformed into 24V/48V, mitigating the risk of accidents caused by circuit shorts and ensuring safe operation even in wet environments.

Automatic Motor Brake System

Unlike manual hoists, our electric chain hoists feature an automatic dual motor brake system. This system ensures simultaneous braking in the event of power failure or switching off, enhancing safety and preventing accidents during lifting operations.

Cost Efficiency

Our electric chain hoists streamline lifting processes, effortlessly handling loads that would typically require multiple workers. By reducing the need for extensive manpower, Cheng Day's electric hoists contribute to cost savings and improved efficiency in your operations.

Wide Range of Lifting Capacities

Whether you're lifting small loads or heavy machinery, Cheng Day offers electric chain hoists with lifting capacities ranging from 1 to 30 tons (30,000 kg), ensuring that we have the perfect solution for your specific needs. Now, welcome to browse our category to discover more models!

Concert Hoist

Entertainment Technology

Cheng Day / Black Bear concert hoists are designed to handle stage and theatrical equipment and enable the safe and accurate positioning of speakers, lighting systems, stage sets, and sceneries. The features and options of Black Bear concert hoist make it the best choice for a demanding customer. Its low weight makes it ideal for touring events. Its compact size permits it to fit inside truss structures. Its quietness makes it ideal for operation during performances, even in theaters. Its CE certification ensures the quality process.

Our product's amazing characteristics and features truly open the gate to creativity and inspiration.

SH D8

ELECTRIC CHAIN HOIST

Legendary in performance, professional riggers around the world have come to rely on the Black Bear SH series for the most demanding and challenging applications. This hoist is available from 250 kg to 2 ton.

SH D8+

ELECTRIC CHAIN HOIST (DIRECT TYPE)

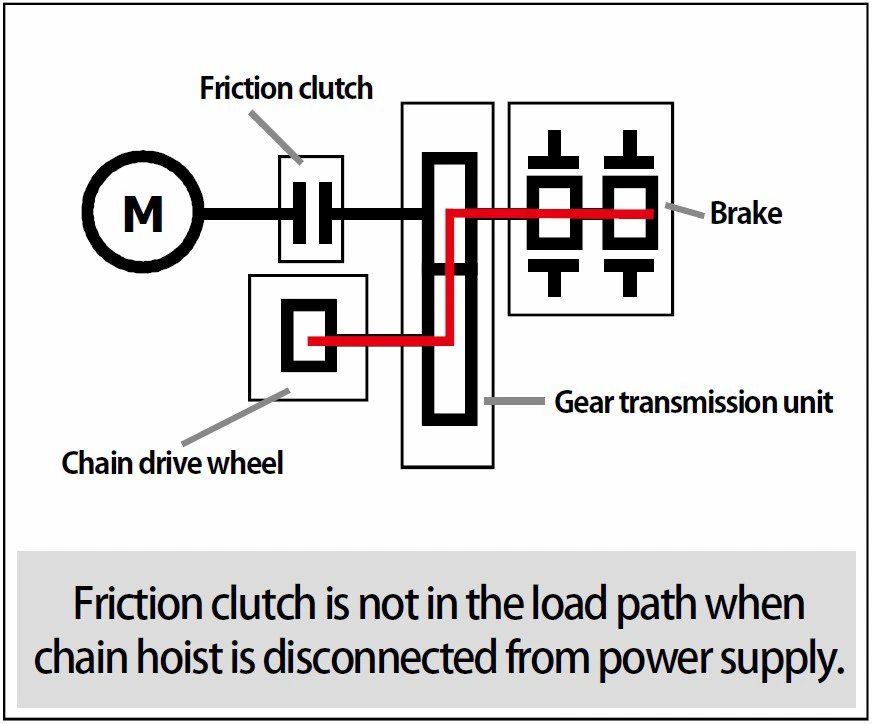

The SH D8+ electric chain hoist, the friction clutch is not in the load path when chain hoist is disconnected from power supply. Acts as a precise overload device; and design factor is 10:1 with a double brake installed. The SH D8+ is in accordance with the VPLT Code of Practice.

Black Bear...Bear the Bright Future.

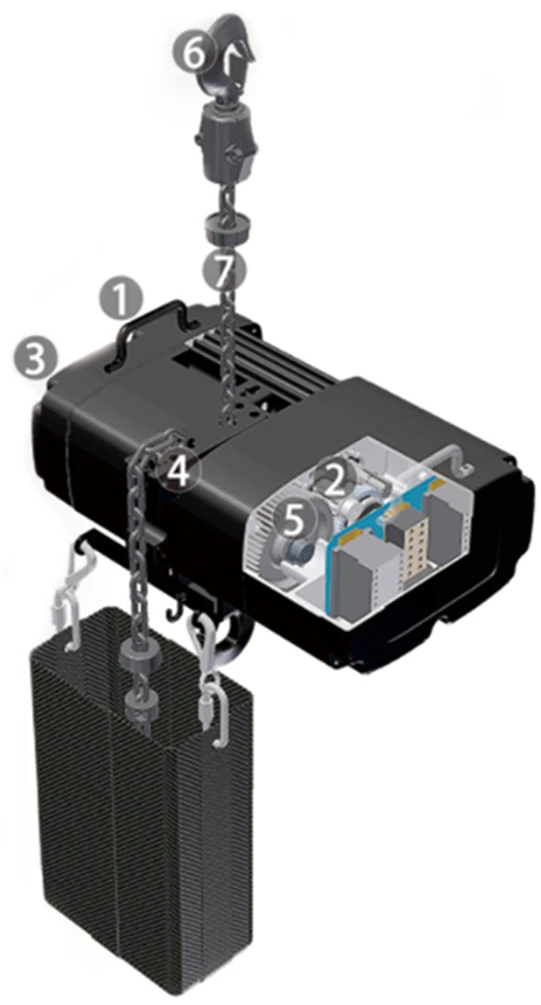

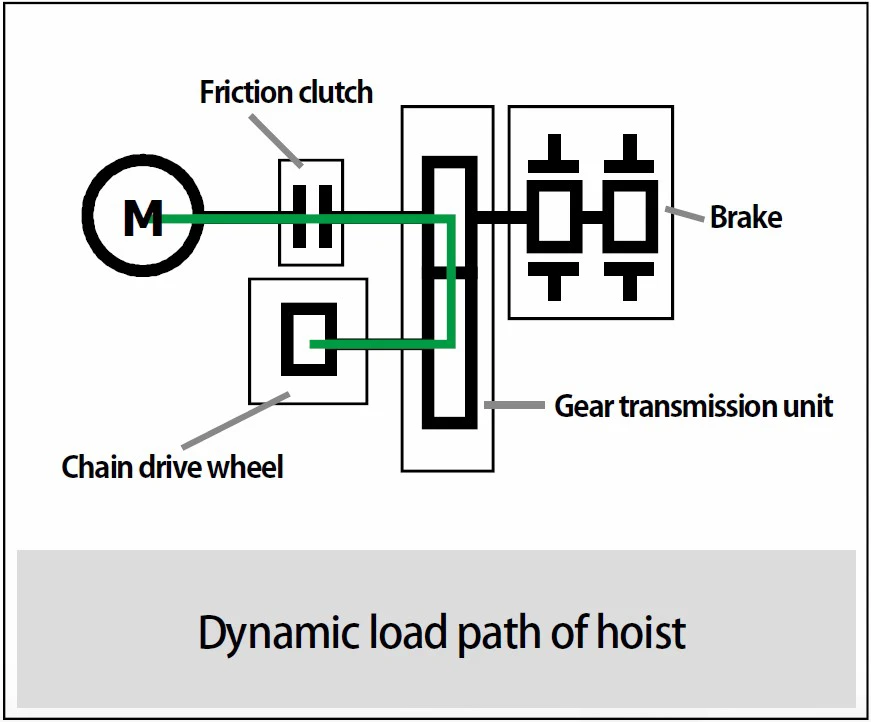

| D81.Motor and electromagnetic brake

2.Overload protectionMechanical overload device- While generated torque is over the friction torque, the overload mechanism will trigger, in which motor keeps running but slipping clutch hold back the hoist from further lifting for the sake of safety.  3.Geared limit switch (Optional)It can be handy adjusted to the required position, setting the chain travelling limits and offering the preventable method for hoist from over winding and damage.  4.Chain Gide

5.GearGear is made of alloy steel with heat treatment for steady operation and less wearing and tearing.  6.Top hookTop hooks apply material SF45C to cast which allow swiveled 360 and are equipped with safety latch to enhance the loading safety.  7.Lad ChainPremium quality and high strength alloy chain, heat treated, used in a variety of sling and tie down applications. |

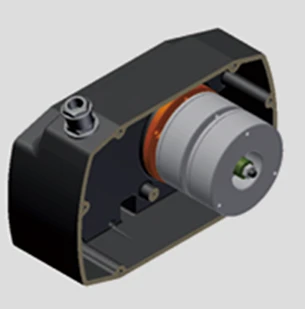

| D8 plus1.Gear

2.Dual brake systemThis system is safer: allows for a secondary braking of action in the event that the primary braking system fails or demagnetized.  3.Overload protection (slipping clutch)Friction clutch is not in the load path when chain hoist is disconnected from power supply. It's mechanical brake. (when reatart, it's unable to lift up due to overload protection).  4.Chain sprocket

|

|  |

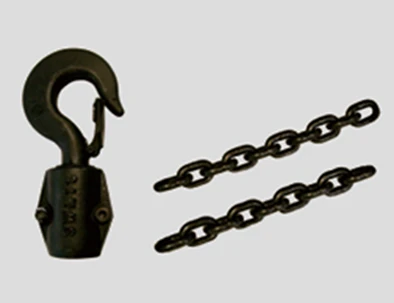

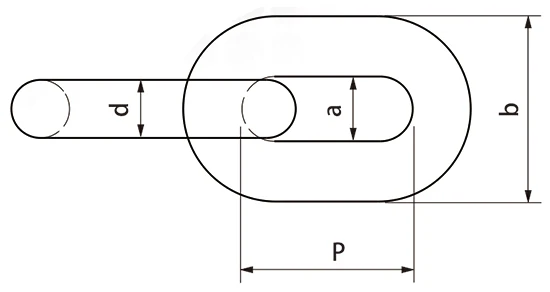

Load Chain

|  |

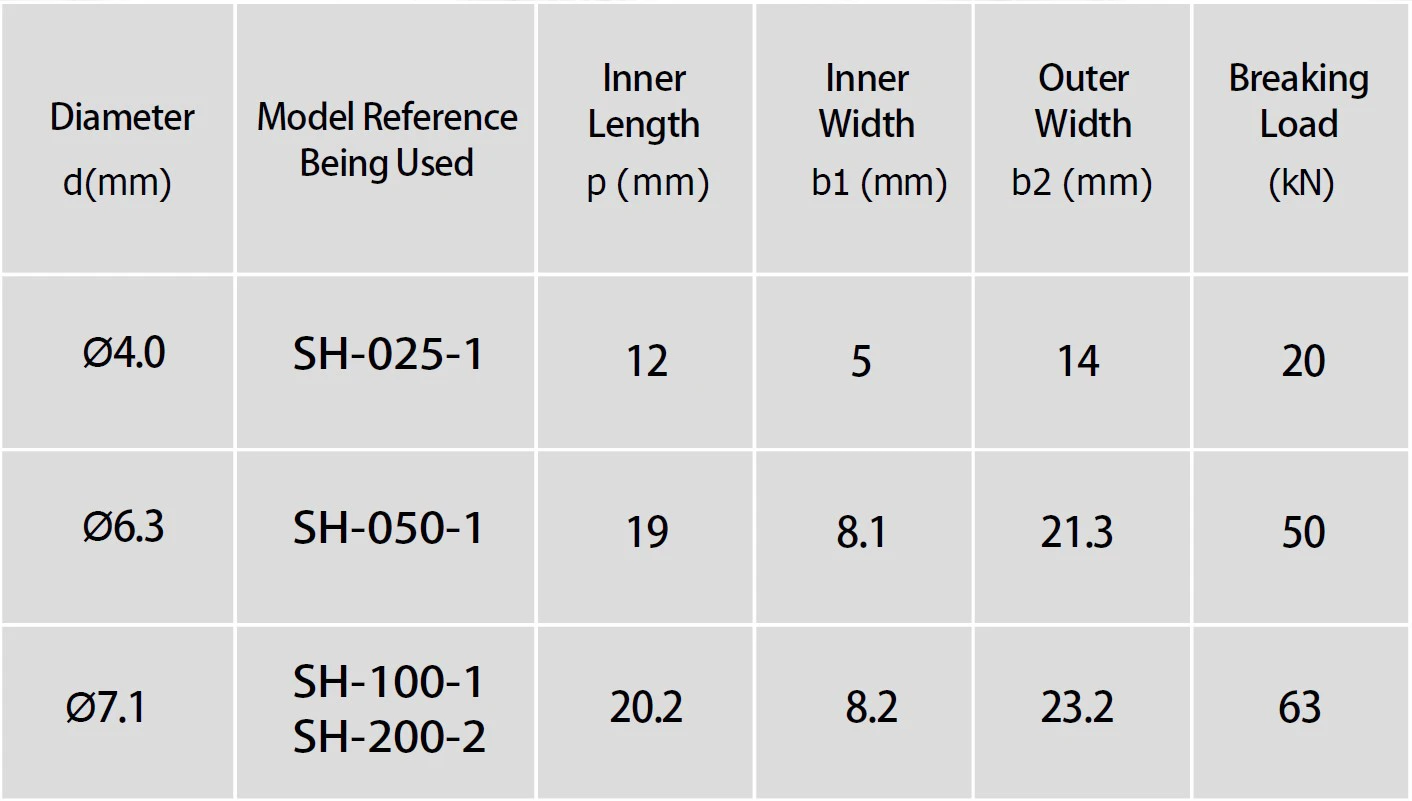

VPLT.VPLT.Standard SR2.0-Special engineering requirements

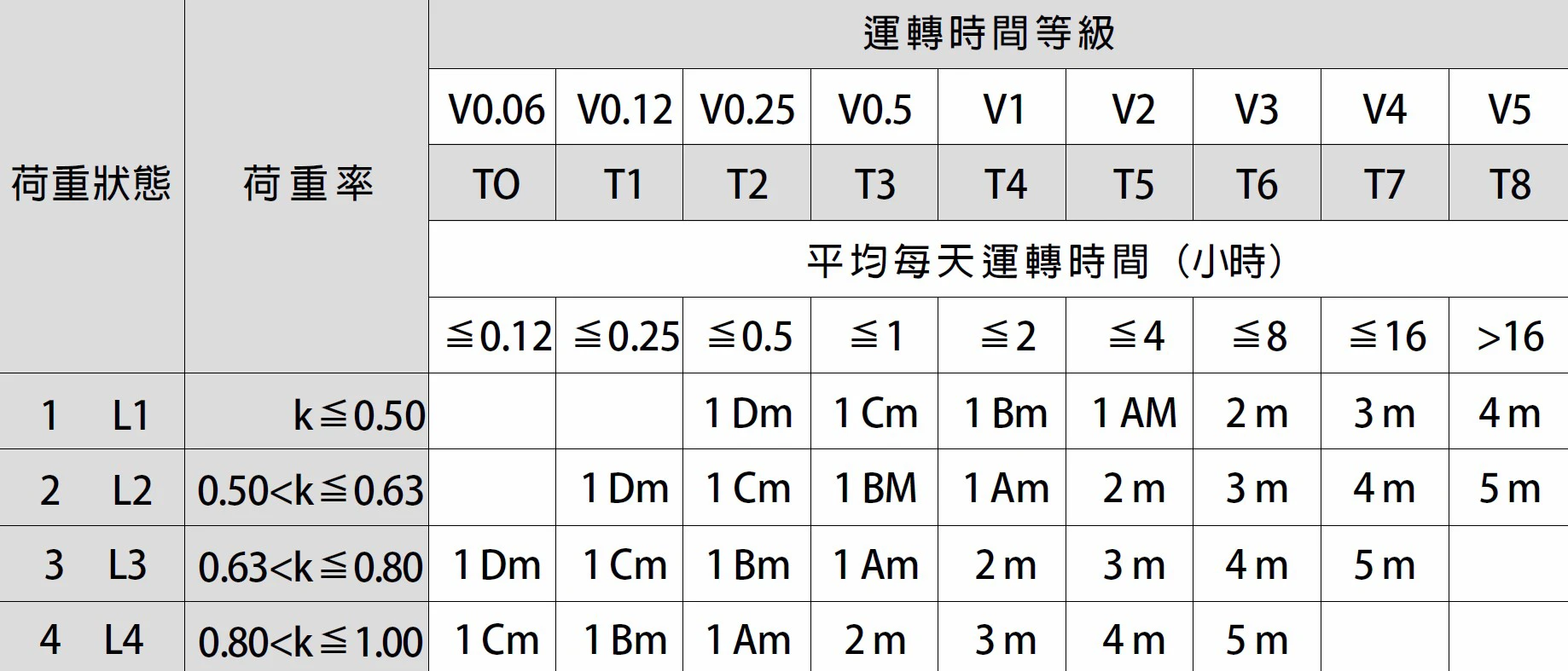

- 1Bm = 400 operating hours under full load in normal use.

- Rated load = load during operation. The sum of the load plus the dynamic forces.

- A friction clutch is permitted if it is not within the load path when the electric chain hoist is disconnected from the power supply. Underload monitoring with a collective shut-down facility is required for guided loads and system loads.

- Overload shut-down/overload monitoring.

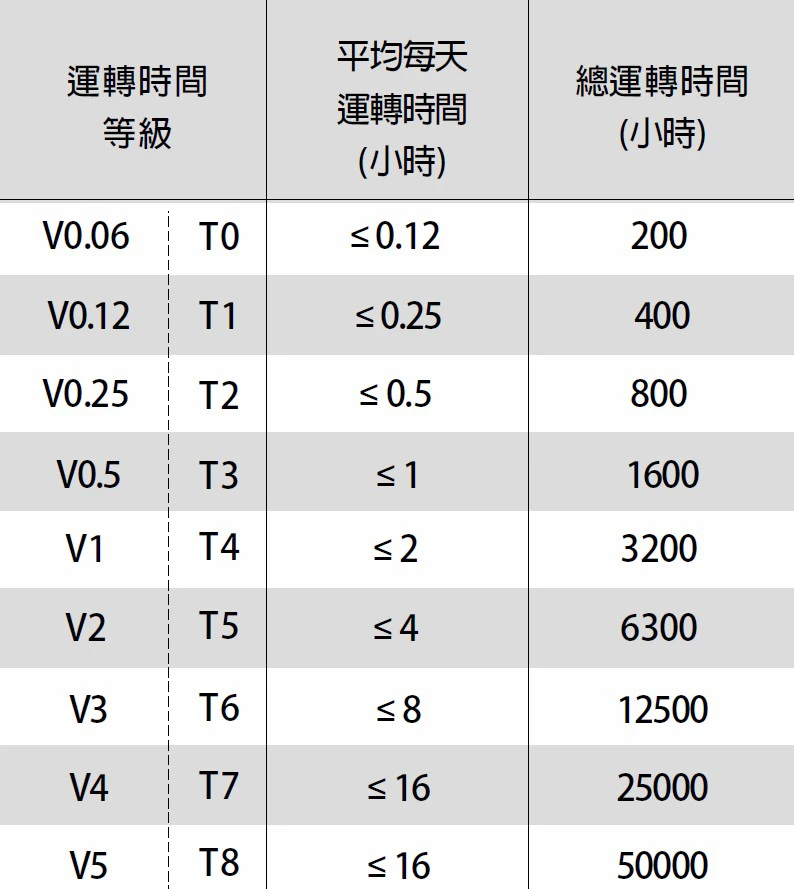

FEM European Joint Standards

ISO/FEM (9.511)

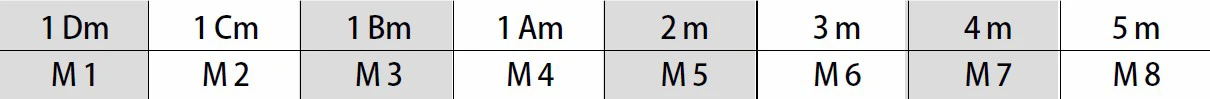

Classification of mechanisms into groups  Classification of mechanisms  | Class of operation time  |

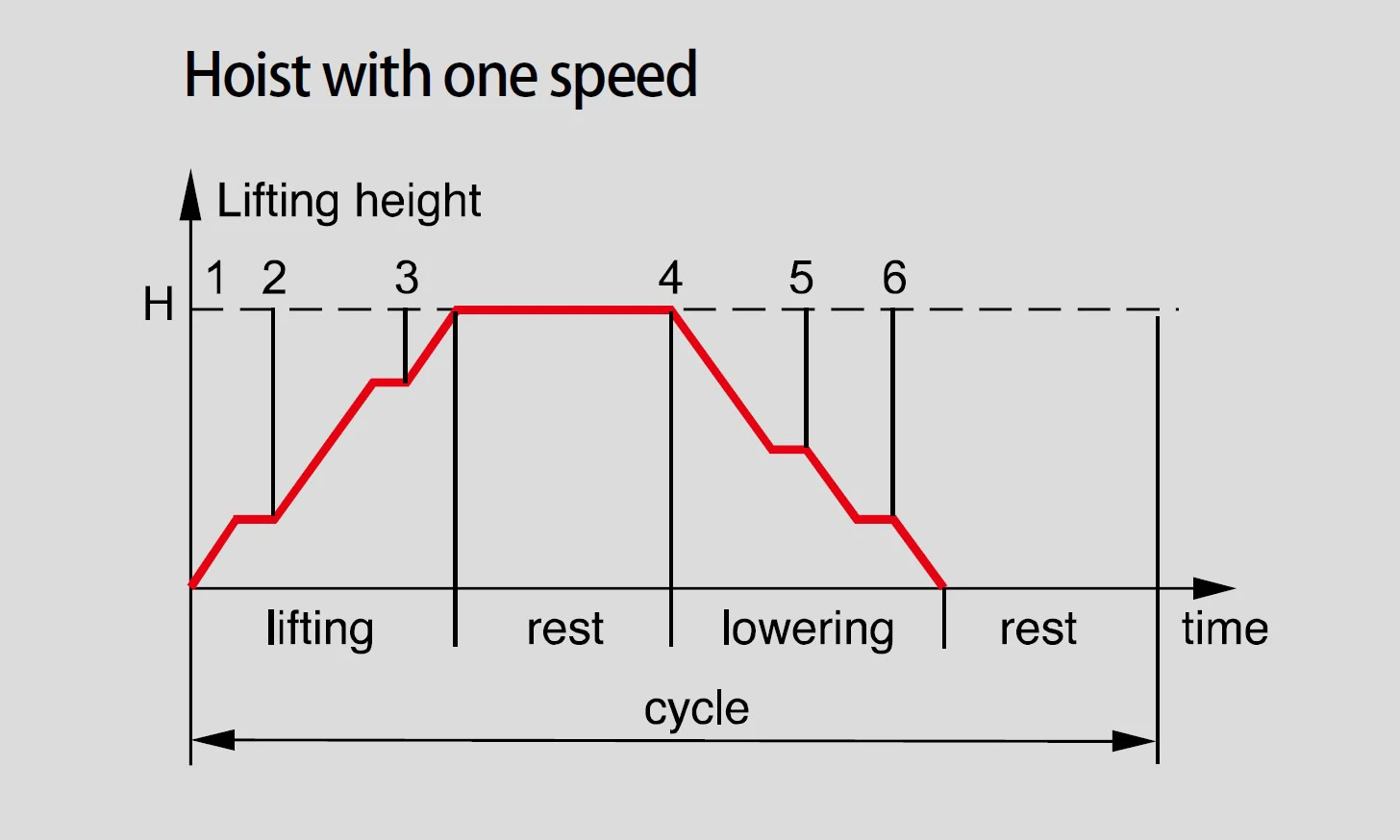

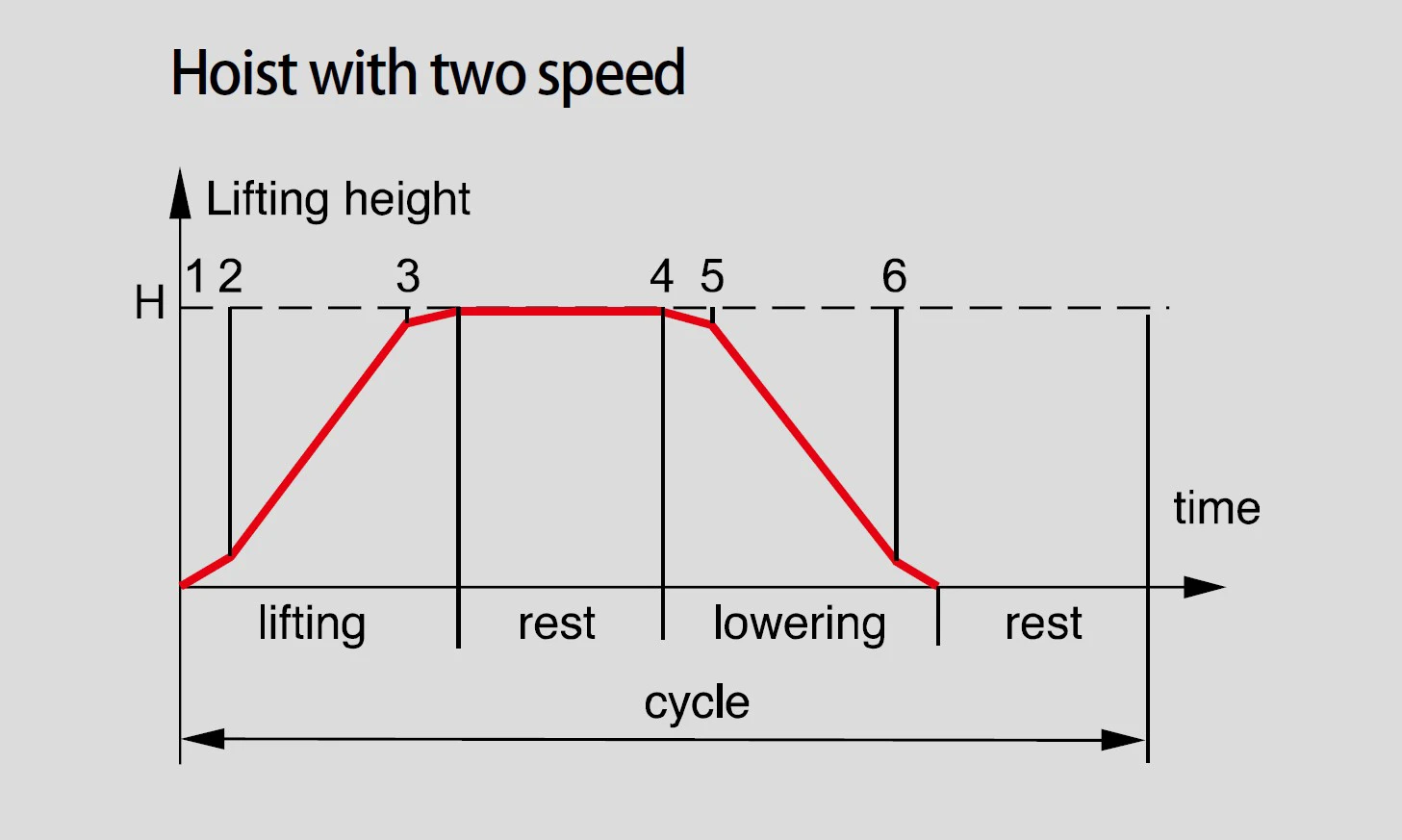

Operation Cycle

|  |